Sustainability

SUSTAINABILITY

Environmental Impact:

A Smarter, Longer-Lasting Choice - Naturally

Basalt materials are lightweight yet remarkably strong. They don't corrode like steel, even in harsh marine or chemically aggressive environments. That means fewer repairs, longer service life, and lower maintenance costs over time-making basalt not just a technical improvement, but a sound financial decision.

From a materials standpoint, basalt is non-conductive, non-toxic, and highly resistant to temperature extremes and UV exposure. And unlike many synthetic materials, basalt products can be fully recycled at the end of their service life. They begin as natural rock and can return to inert, mineral form without polluting the environment or generating waste.

Choosing basalt-based reinforcement and composite systems is a practical way to reduce weight, increase longevity, and improve material efficiency. And while the economic logic often speaks for itself, these choices also align with broader goals of minimizing environmental impact and reducing a project's overall carbon footprint.

The Future Depends On Change

The future of infrastructure is dependent on how resilient the planning, manufacturing, and construction of future projects are. Infrastructure is designed to be safe and last as long as possible. On top of that, infrastructure should have low-life cycle costs and have as little impact on the natural environment as possible. Using composites in projects improves all these facets of infrastructure.

Currently, projects use materials like concrete and steel to construct infrastructure and are considered long-lasting. However, these structures require regular, costly maintenance and have shorter lifespans. Additionally, the manufacturing of steel and concrete produce significant greenhouse gas emissions.. So what can we, as an industry do, to improve the sustainability of infrastructure? The solution lies in the use of composites.

Composites Are The Future

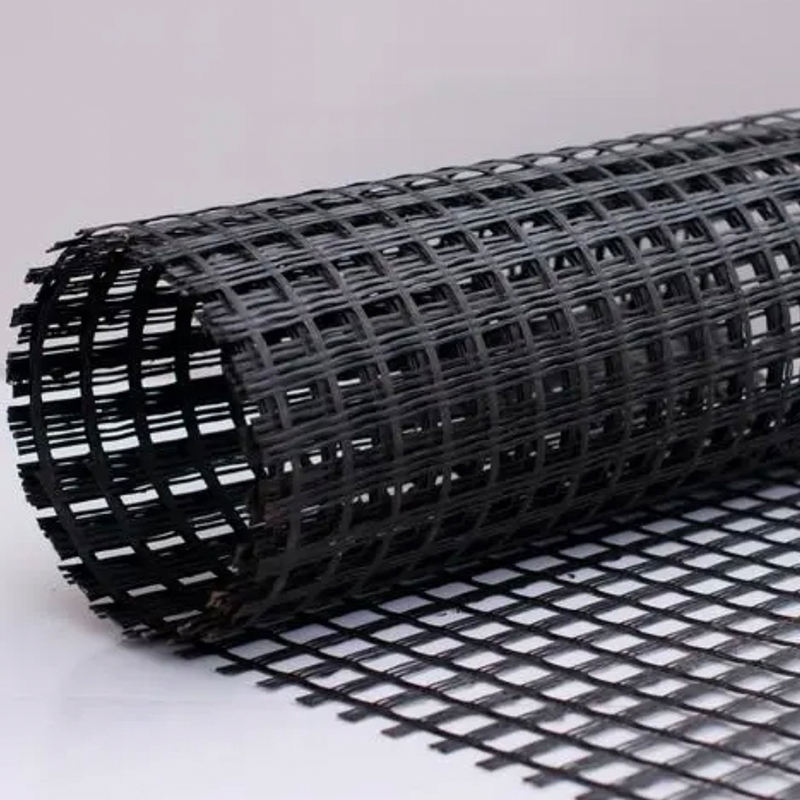

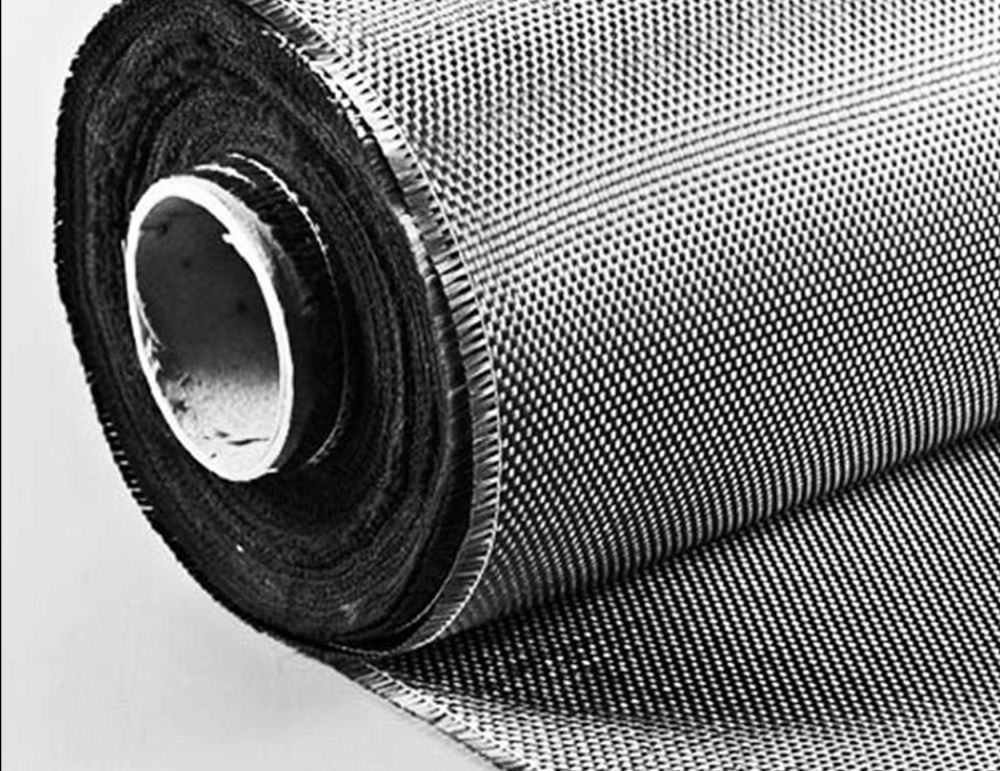

The word "composite" is defined as something made up of various parts or elements. In materials and construction, the word "composites" commonly refesr to fiber-reinforced polymer or FRP composites. FRP Composites are typically made using glass, carbon or basalt fibers, that have been cured in resin. The outcome can be lightweight, high-strength, corrosion-free, and time enduring building material.

Composites were first tested on a boat in 1942, and the boating industry never looked back. Today, composites are used in airplanes, spaceships, helicopters, cars, bicycles, wind turbines, offshore platforms, and most recently as a building material for infrastructure. Basalt International Design & Engineering is known for producing FRP composite arch & beam bridge systems, rebar, sea walls, and utility poles.

Basalt International’s materials have been tested at the University of Maine's Advanced Structures & Composites Center (ASCC) and have proven to last 100+ years with little to no maintenance. Additionally, when using composites in infrastructure, a project's carbon footprint is reduced during all phases of the project; manufacturing, transportation, construction, and maintenance.

A Resource for Resilience

The Institute for Sustainable Infrastructure (ISI) is a non-profit organization that developed and manages Envision, a framework that encourages systemic changes in the planning, design, and delivery of sustainable and resilient infrastructure through education, training, and third-party project verification. To find out more about sustainable infrastructure and how to help advocate, visit sustainableinfrastructure.org

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote