Bridge Systems

Custom-Engineered Bridge Systems (Composite Bridge Systems)

100% Custom design for each project

15-50% Rise/span of single-radius arches

- Made from durable, corrosion-resistant fiberglass, basalt and carbon fiber composite

- Lightweight for easy transportation, handling, and rapid installation

- Ideal for commercial DOT, infrastructure, parks, trails, and remote access

- Low long-term costs

Common Applications

Ideal to use when high-performance, corrosion-resistant infrastructure is desired

Commerical DOT Projects

Replacement of Aging Wooden or Steel Structures

Pedestrian Bridges for Parks and Nature Reserves

Utility Access Bridges In Remote Areas

Emergency or Temporary Crossings

Industry Challenges

Steel or other fibers have significant drawbacks in preparation, usage and longevity

- Steel is expensive and slow to transport, and requires heavy duty cranes to install

- Corrosion and decay in steel or wood bridges exposed to the elements

- High maintenance costs and frequent repairs for traditional materials

- Remote site access, requires lightweight, prefabricated solutions

- Extended installation timelines due to heavy or complex materials

- Environmental impact, with demand for longer-lasting, lower-footprint infrastructure

Material Advantages

Composite Bridge Systems overcome common issues, providing the perfect solution

- Corrosion resistance – basalt composite will not rust, rot, or degrade in harsh environments

- Lightweight strength – high strength-to-weight ratio enables easier transport and faster installation

- Low maintenance – reduces lifecycle costs compared to wood or steel

- UV and moisture resistant – withstands prolonged outdoor exposure without structural compromise

- Non-conductive – ideal for applications near power infrastructure or sensitive equipment

- Long service life – engineered for decades of performance without deterioration

Business Benefits

Basalt International can improve performance, project timelines, and costs

- Lower total cost of ownership – reduced maintenance and replacement costs

- Faster project timelines – rapid installation minimizes downtime and labor expenses

- Increased project flexibility – custom engineering adapts to unique site conditions and requirements

- Improved ROI – long-lasting, resilient infrastructure supports long-term planning and budgeting

- Enhanced safety and reliability – consistent, high-performance material ensures structural integrity

Product Offerings

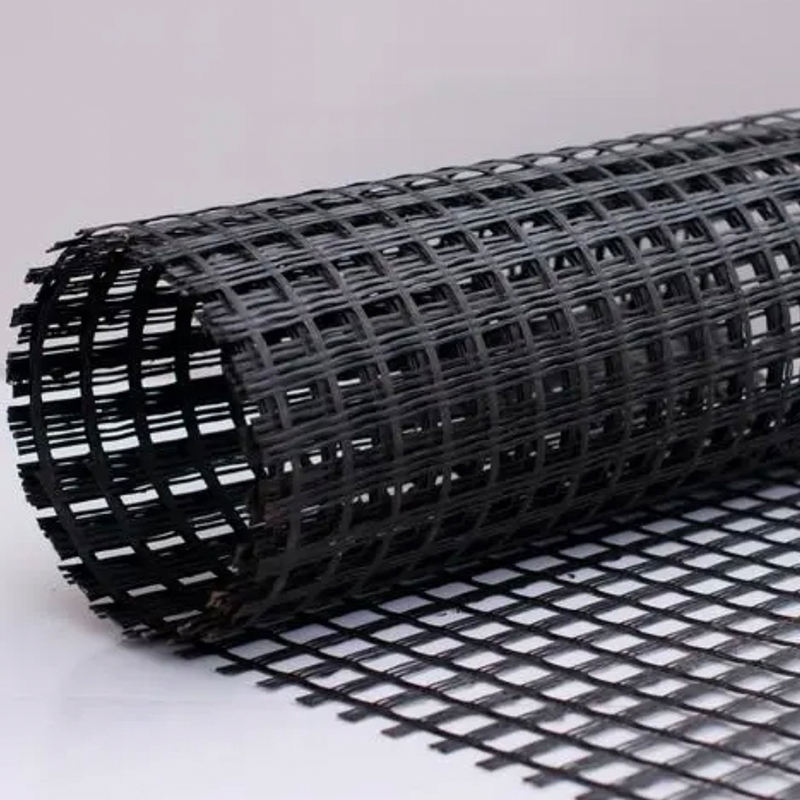

Composite Girders

- Composite tub beams require no concrete fill.

- Cast-in-place, precast transverse, and precast longitudinal deck options.

- Depth and camber easily adjusted based on project requirements.

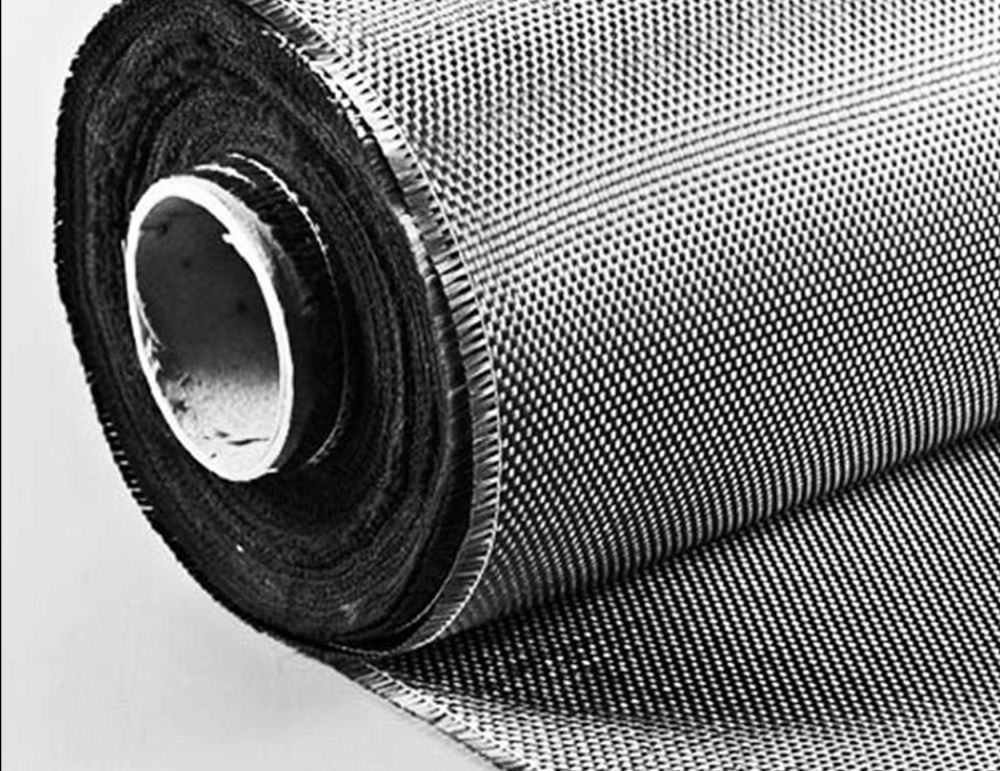

Composite Arches

- Lightweight FRP arch tubes filled with concrete on site.

- Can be handled with small, lightweight equipment.

- Reduces concrete needed by about 4/5ths compared to typical concrete span bridges.

- Highly customizable based on project description.

Composite Decking

- Light weight and very strong – easy to transport, move, and install

- Exceeds competitors' standards by utilizing an improved resin system that provides higher durability, UV protection, and better alkali resistance characteristics.

- Corrosion resistant which aids in designing a structure with a much longer service life than steel or concrete decking.

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote