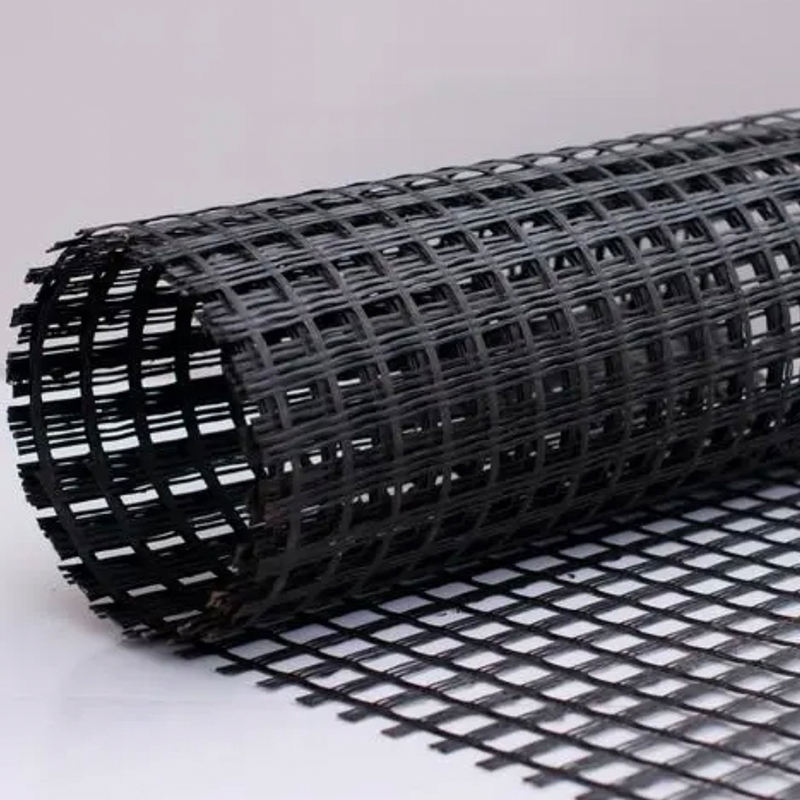

Basalt Fabric

Basalt fabric is a high-performance textile made from continuous basalt fiber

100% Made from natural volcanic rock

- High Thermal Resistance: Withstands temperatures up to 1,000°C (1,832°F) without melting or emitting toxic fumes

- Exceptional Strength-to-Weight Ratio: Offers superior tensile strength while remaining lightweight and flexible

- Corrosion and Chemical Resistant: Performs reliably in harsh environments, including marine and chemical settings

- Eco-Friendly: Made from abundant basalt rock with minimal environmental impact and no additives

- Flame Retardant & Non-Combustible: Ideal for fire protection applications

- Acoustic and Thermal Insulation: Provides excellent insulating properties for construction and industrial use

Common Applications

Basalt fabric blends the strength of modern composites with the integrity of natural materials

Reinforcement in concrete, plaster, and composite panels

Lightweight, fire-resistant liners and structural parts

Boat hull reinforcement, anti-corrosion linings

Thermal insulation, protective gear, welding blankets

Natural aesthetic appeal for eco-conscious interiors

Industry Challenges

Basalt fabric faces common adoption challenges in new material markets

- Limited Market Awareness: Many manufacturers and designers are still unfamiliar with basalt fiber's benefits compared to traditional materials like fiberglass or carbon fiber

- Higher Initial Costs: Although cost-effective long-term, the upfront cost of basalt fabric can be higher due to limited production scale and supply chain development

- Processing Compatibility: Some fabrication processes and equipment need adjustment to accommodate basalt's unique properties, which can deter adoption

- Supply Chain Constraints: Limited producers and geographic challenges can lead to inconsistent availability and longer lead times

- Lack of Standardization: The absence of widely recognized industry standards for basalt products creates uncertainty for engineers and specifiers

Material Advantages

Basalt fabric offers material that is a durable and non-toxic alternative to synthetics

- High Heat Resistance: Withstands extreme temperatures (up to ~1,000°C) without melting, degrading, or releasing toxic fumes

- Superior Strength-to-Weight Ratio: Offers excellent tensile strength and durability while remaining lightweight and flexible

- Corrosion & Chemical Resistance: More resistant to corrosive environments, does not absorb moisture, resistant to UV, and being rock, does not biologically degrade —ideal for harsh environments

- Eco-Friendly & Non-Toxic: Made from 100% natural volcanic rock with no additives, making it safe for humans and the environment

- Excellent Insulation Properties: Provides strong thermal and acoustic insulation, making it useful for energy-efficient and noise-sensitive applications

Business Benefits

Basalt fabric enhances performance, sustainability, and cost efficiency

- Sustainable Market Differentiation: Positions your brand as an eco-conscious leader by offering a natural, non-toxic alternative to synthetic materials

- Long-Term Cost Savings: Durability, corrosion resistance, and low maintenance reduce lifecycle costs across industrial and construction applications

- Growing Market Demand: Taps into expanding markets for green building, lightweight composites, and fire-resistant materials

- Regulatory Compliance & Risk Reduction: Helps meet stricter environmental, health, and fire safety standards with a naturally compliant material

- Versatile Application Potential: Enables product diversification across multiple industries—construction, automotive, aerospace, marine, and consumer goods

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote