Sea Walls

Custom-Engineered Sea Walls

100% custom design for each project

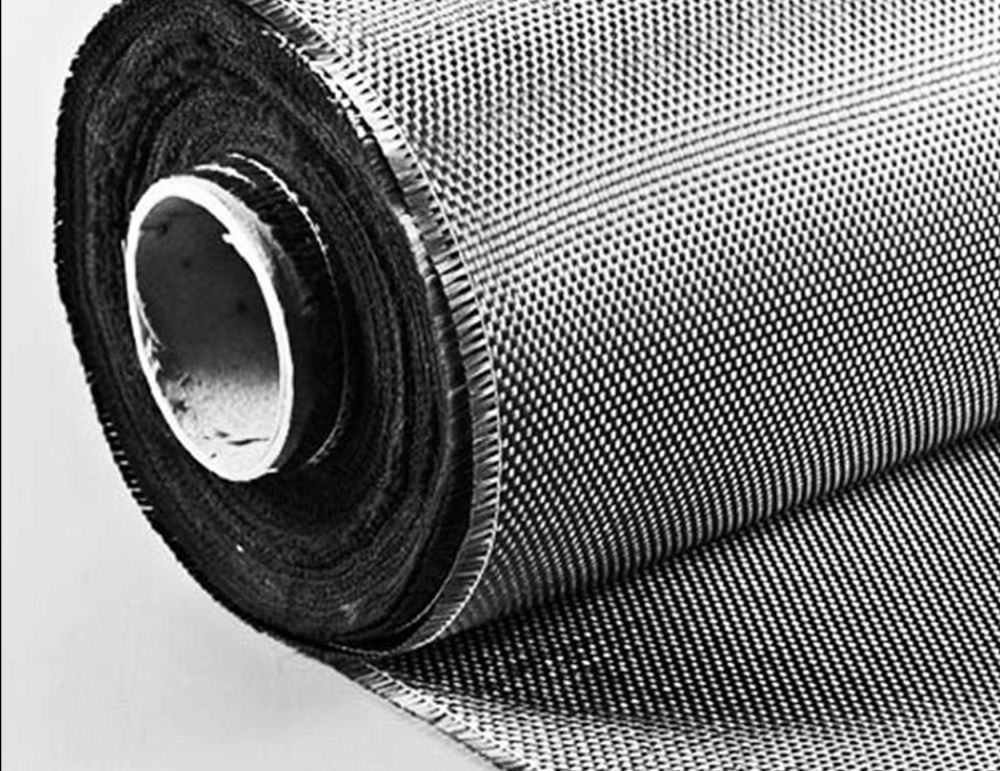

- Made from abundant, naturally occurring basalt rock—non-toxic, non-corrosive, and fully recyclable

- Resilient: Exceptionally strong and saltwater-resistant, with a lifespan that exceeds conventional materials

- Adaptable: Customizable to meet the specific needs of diverse coastlines, from urban harbors to rural shorelines

- Carbon-Conscious: Significantly lower embodied carbon footprint than conventional sea wall materials, contributing to climate resilience efforts

Common Applications

Ideal to use when high-performance, durable infrastructure is desired

Coastal Erosion Control – Safeguard vulnerable shorelines from storm surge and wave impact

Harbor and Marina Infrastructure – Reinforce docks, piers, and waterfront facilities with long-lasting protection

Climate Adaptation Projects – Support nature-based solutions in resilience planning for rising sea levels

Eco-Tourism and Public Waterfronts – Integrate into sustainable landscape design with a natural aesthetic

Industrial Coastal Zones – Provide corrosion-resistant barriers for energy, shipping, and port operations

Industry Challenges

Steel or other fibers have significant drawbacks in preparation, usage and longevity

- Accelerating Coastal Erosion – Traditional materials degrade quickly under constant wave action and rising sea levels

- High Carbon Footprint of Concrete – Conventional sea walls rely heavily on cement, a major contributor to global CO₂ emissions

- Corrosion and Maintenance Costs – Steel-reinforced structures are prone to rust and require frequent, costly upkeep

- Disruption to Marine Ecosystems – Many coastal defense systems damage habitats and fail to integrate with natural environments

- Limited Design Flexibility – Standard sea wall solutions often lack adaptability for unique shoreline conditions and climate resilience planning

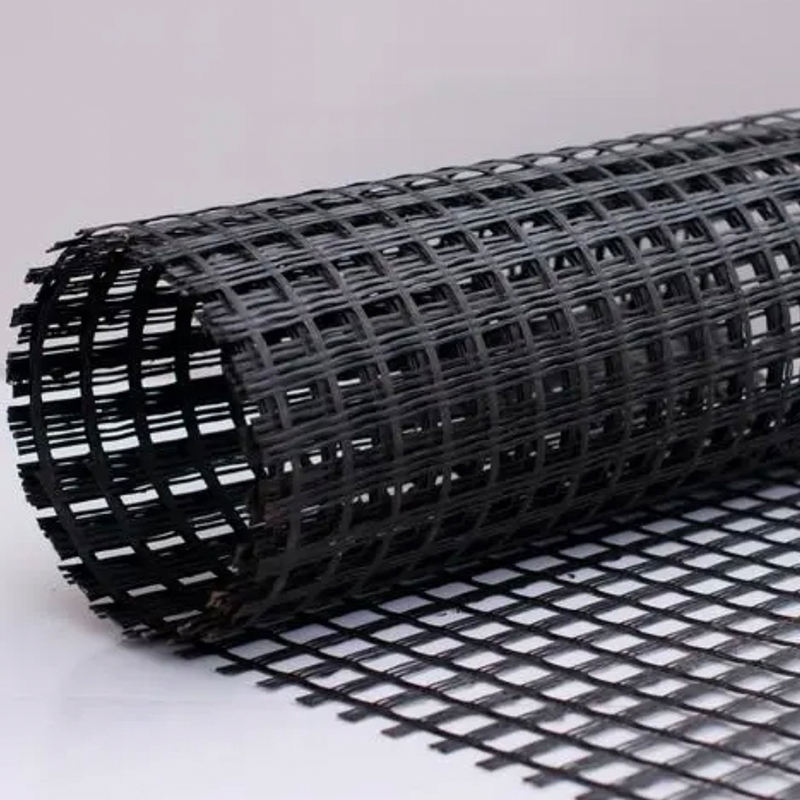

Material Advantages

Sea Walls outperform traditional materials in protecting the coastal environment

- Low shipping & Installation Costs

- High Strength-to-Weight Ratio – Basalt delivers exceptional durability without the bulk of traditional materials

- Corrosion & Saltwater Resistant – Naturally impervious to moisture and chemical degradation, ideal for marine environments

- Thermally Stable & Non-Combustible – Maintains integrity under extreme temperature shifts and fire exposure

- Low Environmental Impact – Basalt is abundant, non-toxic, and requires minimal processing, reducing emissions

- Long Lifespan with Minimal Maintenance – Outperforms concrete and steel in longevity and lifecycle costs

Business Benefits

Basalt International can improve performance, project timelines, and costs

- Reduced Lifecycle Costs – Durable basalt materials lower long-term repair, replacement, and maintenance expenses

- Faster Project Approval – Environmentally responsible design aligns with regulatory goals and ESG criteria

- Market Differentiation – Position your projects as leaders in climate-resilient, nature-based infrastructure

- Supply Chain Stability – Basalt is widely available and less vulnerable to price volatility compared to steel or cement

- Sustainability Edge – positions your project as forward-thinking and environmentally responsible

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote