Utility Poles

High Performance, Durable Infrastructure

3x stronger than steel

80–100 year lifespan

- High Strength & Lightweight: Basalt fiber poles are up to 3x stronger than steel by weight and significantly lighter than wood or concrete, reducing transportation and installation costs

- Lower Mortality rates upon automobile impact

- Dimensionally stable: Do not warp, bend or twist

- Corrosion & Weather Resistance: Naturally resistant to moisture, UV radiation, chemicals, and extreme temperatures, making them ideal for coastal, humid, or corrosive environments

- Fire & Pest Resistant: Non-combustible and immune to termite, insect, and fungal attacks, eliminating common maintenance concerns.

- Long Service Life: Designed to last 80–100 years with minimal degradation, lowering total lifecycle costs

- Eco-Friendly & Sustainable: The poles are non-toxic and recyclable. Can be made in any color.

- Non-Conductive & Electromagnetically Neutral: Safe for electrical applications with no interference to signals or induced currents

Common Applications

Ideal to use when high-performance, durable infrastructure is desired

Electrical Transmission & Distribution

Telecommunications & Broadband Networks

Lighting Infrastructure

Off-Grid & Remote Installations

Coastal & High-Humidity Environments

Industry Challenges

Steel and wood have significant drawbacks in preparation, usage and longevity

- Corrosion & Degradation of steel and wood poles in coastal, humid, or chemically exposed environments

- Frequent Maintenance & Short Lifespan of traditional materials, driving up lifecycle costs

- Supply Chain Pressures and deforestation impacting availability and cost of wood poles

- Heavy Weight of Concrete & Steel poles complicating transport and installation logistics

- Fire Risk in wildfire-prone regions due to combustible wooden poles

- Pest Infestation & Rot reducing the integrity of wood over time

- Electromagnetic Interference (EMI) and conductivity risks from metal poles in sensitive utility applications

- Increased Regulatory & Environmental Scrutiny around material sourcing, carbon footprint, and end-of-life disposal

Material Advantages

Basalt Utility outperform traditional materials

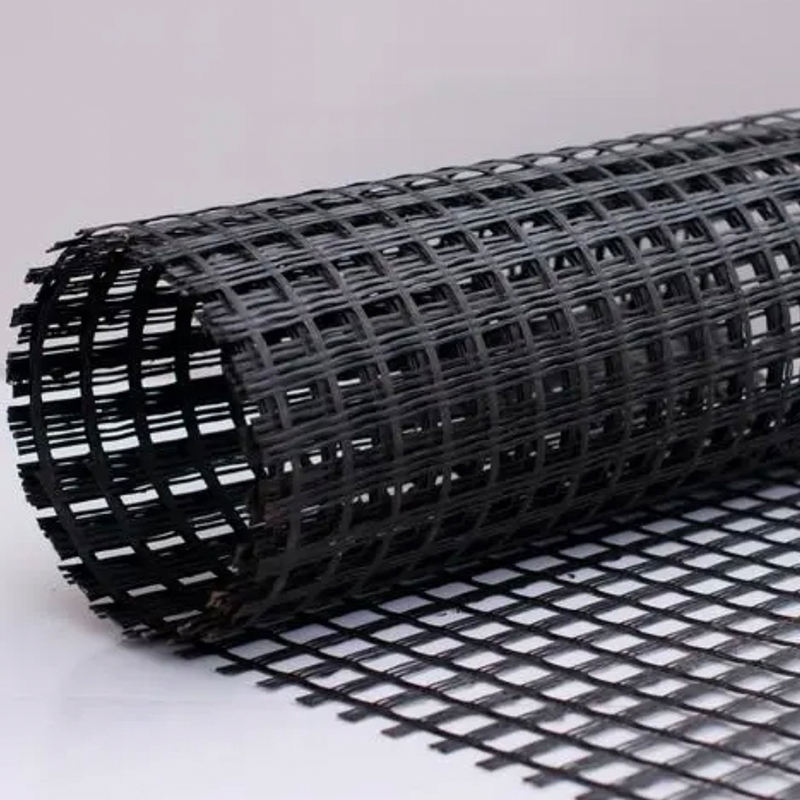

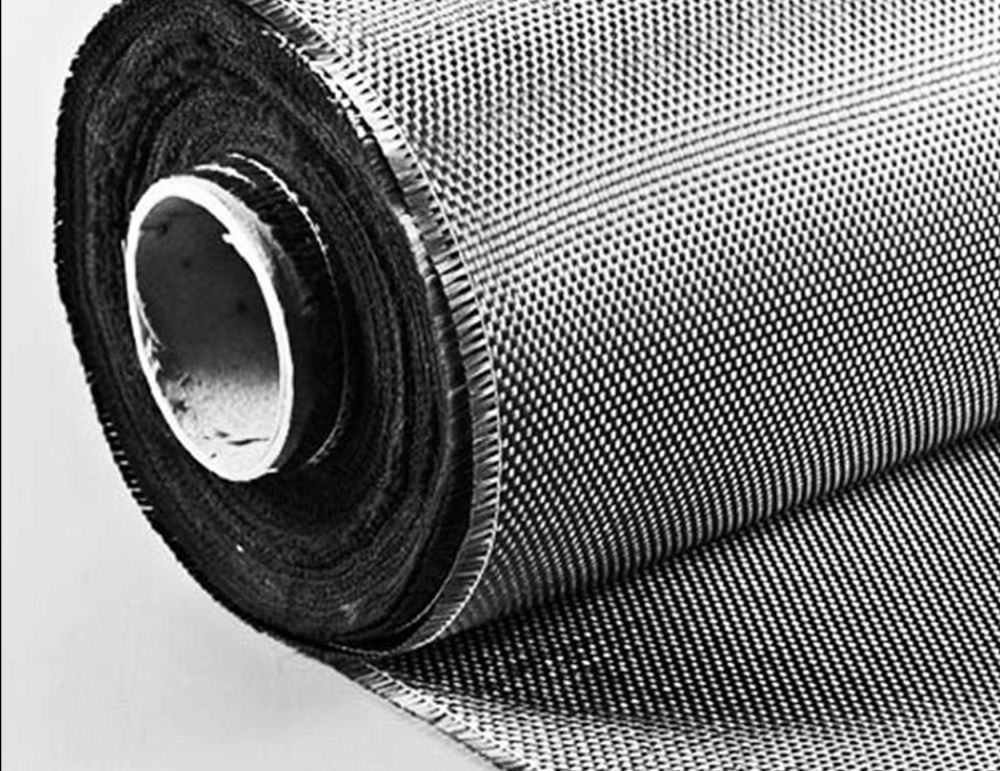

- Exceptional Strength-to-Weight Ratio: Basalt fiber is stronger than steel by weight, enabling lightweight yet load-bearing structures that are easier and cheaper to install

- High Corrosion Resistance: Unlike steel or wood, basalt fiber is naturally inert to salt, moisture, chemicals, and UV radiation—ideal for coastal or chemically exposed environments

- Fire-Resistant and Non-Combustible: Basalt has a high melting point (~1450°C), providing excellent fire resistance, crucial in wildfire-prone regions

- Naturally Non-Conductive: Basalt fiber is electrically insulating and does not conduct heat or electricity, improving safety in utility and telecom applications

- Durability and Longevity: Resistant to rot, rust, pests, and environmental degradation—basalt poles offer a lifespan of 80–100 years with minimal maintenance

- Sustainable and Eco-Friendly: Made from naturally occurring volcanic rock, basalt fiber production emits significantly less CO₂ than steel or fiberglass. It’s non-toxic, recyclable, and resource-abundant

- Lightweight for Easier Transport and Installation: Basalt composite poles are significantly lighter than concrete or steel, reducing transport emissions, installation equipment needs, and labor costs

- Thermal Stability: Maintains mechanical integrity across extreme temperatures, making it ideal for both cold and hot climates

- Electromagnetic Neutrality: Basalt fiber does not interfere with radio or telecom signals, unlike steel or aluminum structures

Business Benefits

Basalt International can improve performance, project timelines, and costs

- Lower Lifecycle Costs: Minimal maintenance and extended lifespan (80–100 years) reduce total cost of ownership compared to wood, steel, or concrete poles

- Reduced Installation & Logistics Costs: Lightweight material lowers transport, handling, and equipment expenses, enabling faster deployment and smaller crews

- Minimized Downtime & Service Interruptions: Enhanced durability and resistance to environmental stressors reduce pole failure and repair frequency, improving service reliability

- Future-Proof Against Regulations: Eco-friendly composition aligns with evolving environmental, carbon reporting, and sustainability regulations—mitigating compliance risk

- Resilient Infrastructure Investment: Fire-, rot-, pest-, and weather-resistant poles offer reliable performance in high-risk or climate-vulnerable regions, improving ROI on infrastructure

- Sustainable Brand Differentiation: Utilities, municipalities, and developers gain a competitive edge by adopting low-carbon, nature-based solutions aligned with ESG goals

- Improved Worker Safety: Non-conductive, lightweight poles reduce hazards during installation and maintenance, contributing to a safer work environment

- Simplified Supply Chain: Basalt is an abundant natural resource, reducing dependency on volatile timber or steel markets and ensuring consistent material availability

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote