Basalt FRP Rebar

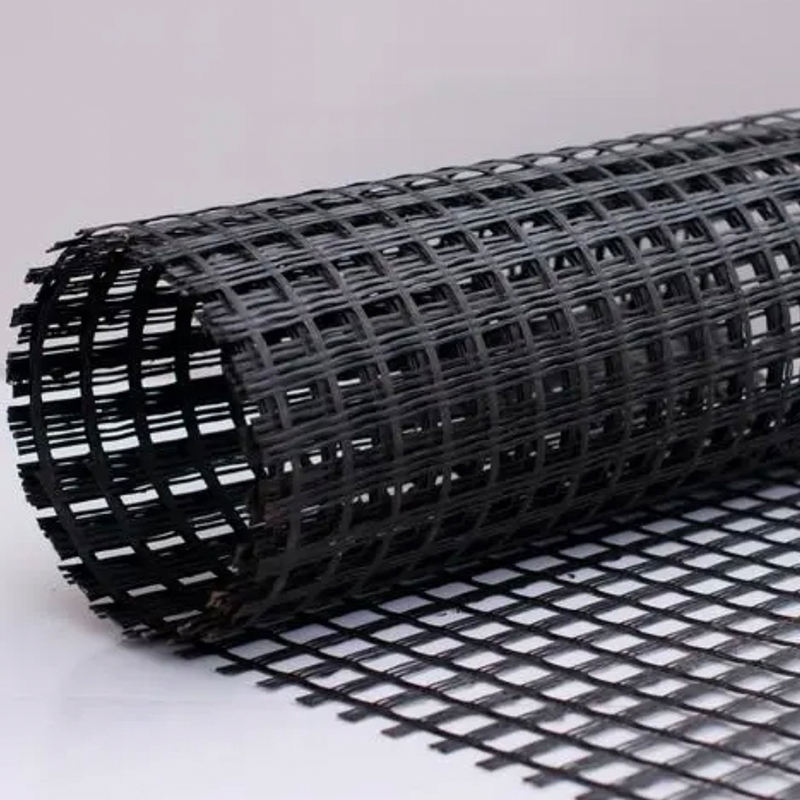

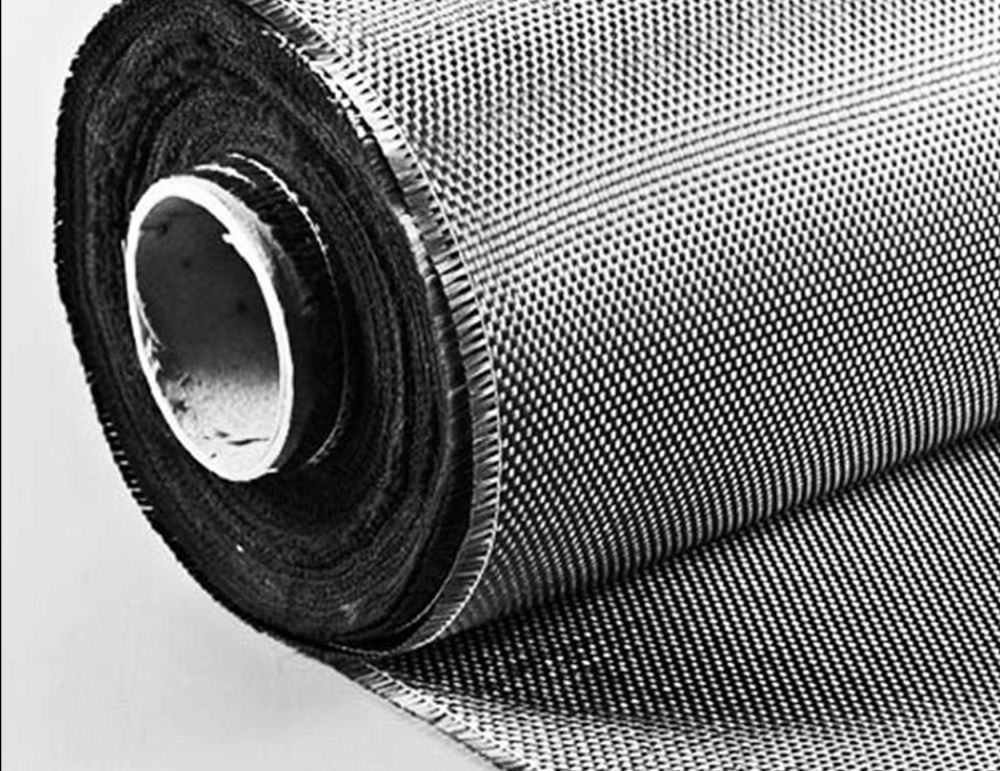

Basalt fiber reinforced polymer rebar (BFRP) is made from basalt roving

4-6× lighter than steel

30% improvement to concrete EPD

- Begins in the form of strands, which are laid parallel to one another

- The basalt strands are then fused with resin

- Strands spiral around the shaft, providing better adhesion to concrete

- Available in an outer diameter of 4 to 24 mm

- Numerous lengths and packaging options

Common Applications

Basalt rebar can be used in a variety of building and product applications

Road Construction

Railroad Construction

Residential Construction

Commercial and Industrial Construction

Concrete Products, like Jersey Barriers

Industry Challenges

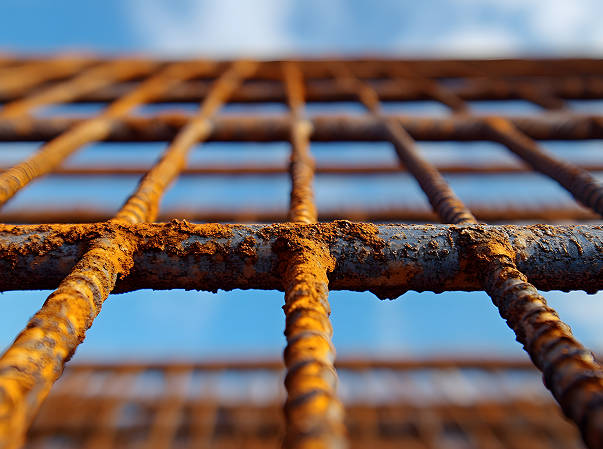

Traditional steel rebar presents several critical limitations

- Heavy to transport, crane and install

- Relatively heavy material weighs down structures

- Steel rusts, causing corrosion within concrete

- Steel conducts electricity and does not insulate

- Steel rebar has a life of only 30 to 50 years

- Does not benefit Environmental Product, Declarations (EPD)

Material Advantages

BFRP is a breakthrough alternative to steel rebar

- 4-6x lighter than steel with the same strength

- Corrosion resistant - will not rust

- Non-ferrous; insulates and won’t carry current

- 100+ years service life

- Improves concrete EPD by 30%

Business Benefits

Not only is BFRP stronger and lighter, it saves you money in multiple ways

- 40% less expensive than the steel equivalent

- 4x transportation cost savings

- 3-4x faster installation, saving labor costs

- Dramatically lower lifetime cost of ownership

- Natural material appeals to projects seeking sustainability

Key Specifications

Comparative Properties of BFRP and Steel Rebar

| Properties | Basalt Rebar | Steel Rebar |

|---|---|---|

| Density | 2 T/m3 | 7.5 T/m3 |

| Corrosion | Corrosion-resistant Material of the first group of chemical resistance | It breaks down with the release of corrosion products |

| Thermal Conductivity | oW/m2˚C | 48W/m2˚C |

| Tensile Strength | 1200 MPa | 390 MPa |

| Working Temperature | from -70 to +100˚C | from -70 to +50˚C |

| Electrical Properties | Dielectric | Electrically Conductive |

| Ecological Safety | Environmentally friendly - does not emit harmful and toxic substances | Fails and is difficult to extract and recycle |

| Shape Retention Under Load | Straight line with elastic linear dependence under load before failure | Curved line with yield plate under load |

| Transportation | Coils of size D =1.15m | Rods 6-12 m long |

| Saving Resources in Use | Stable prices; Savings in transportation due to weight reduction; No welding machine used | No price stability; Expensive to transport and handle; Needs a welding machine as well as fire safety office when cutting |

| Durability | Predicted durability of at least 80 years | Based on building codes |

Order Sizes, Weights, and Lengths for Basalt FRP Rebar

| US | Metric | Weight for 1 running meter (g) | Qty of running meters in MT | Package |

|---|---|---|---|---|

| 4mm | 30 | 33,333 | Coil of 200 rm | |

| 6mm | 50 | 20,000 | Coil of 200 rm | |

| 7mm | 75 | 13,333 | Coil of 200 rm | |

| 8mm | 90 | 11,111 | Coil of 200 rm | |

| #3 | 10mm | 125 | 8,000 | Coil of 200 rm |

| #4 | 12mm | 195 | 5,128 | Whips norm 11.7m |

| 14mm | 270 | 3,704 | Whips norm 11.7m | |

| #5 | 16mm | 350 | 2,857 | Whips norm 11.7m |

| 18mm | 450 | 2,222 | Whips norm 11.7m | |

| #6 | 20mm | 630 | 1,587 | Whips norm 11.7m |

| #7 | 22mm | 630 | 1,587 | Whips norm 11.7m |

| 24mm | 760 | 1,316 | Whips norm 11.7m |

Contact an Expert

Please contact us if you have any questions about our products. One of our experts will get back to you as soon as possible.

Contact Us NowStart a Quote

To begin the purchase process, click below and answer a few preliminary questions. We'll get back to you with more information as soon as possible.

Start Quote